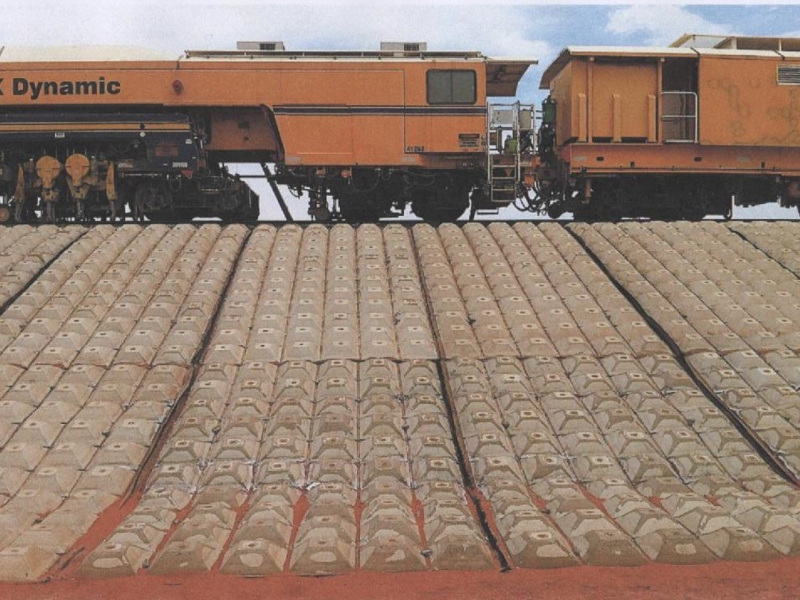

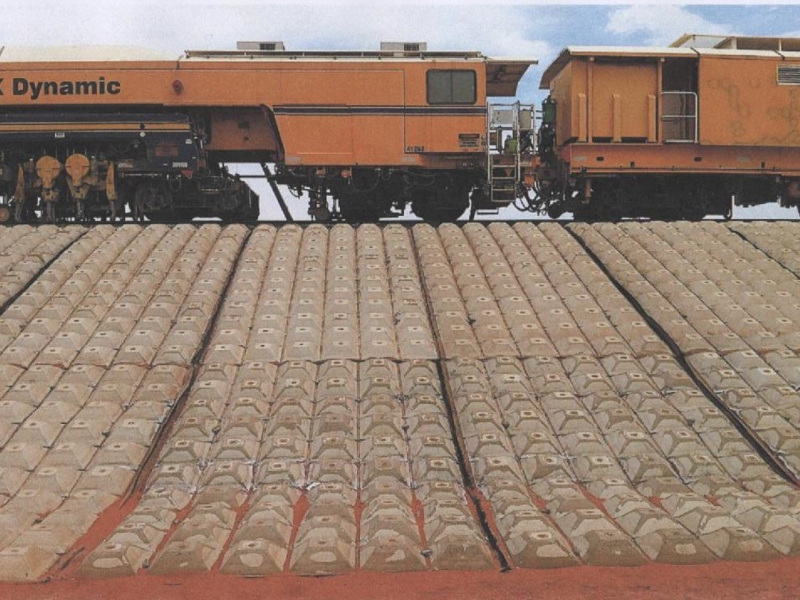

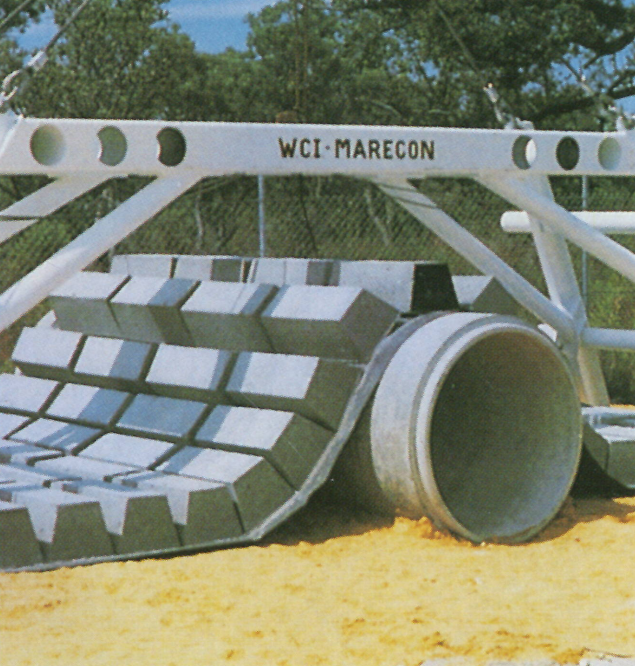

FLEXMAT™ gravity anchors and mattresses are used for pipeline stabilisation, scour control around structures, impact protection, and as spacers at pipeline or cable crossings. They have been successfully applied in Australian waters, particularly on the North West Shelf, as well as overseas.

FLEXMAT™ gravity anchors provide an alternative to weight coating or minimize its thickness, resulting in a significant reduction in required supplementary weight per linear meter and overall cost. The use of gravity anchors also increases the allowable free span of the pipeline, reducing the risk of overstressing.

FLEXMAT™ provides a cost-effective solution for erosion control and slope stabilisation than traditional erosion control solutions like riprap. It is also easy to install and maintain.

Compared to alternative methods such as trenching, mechanical anchoring, and rock dumping, FLEXMAT™ gravity anchors are more cost-effective and reliable. These alternative methods have a substantial failure record, especially during extreme sea states.